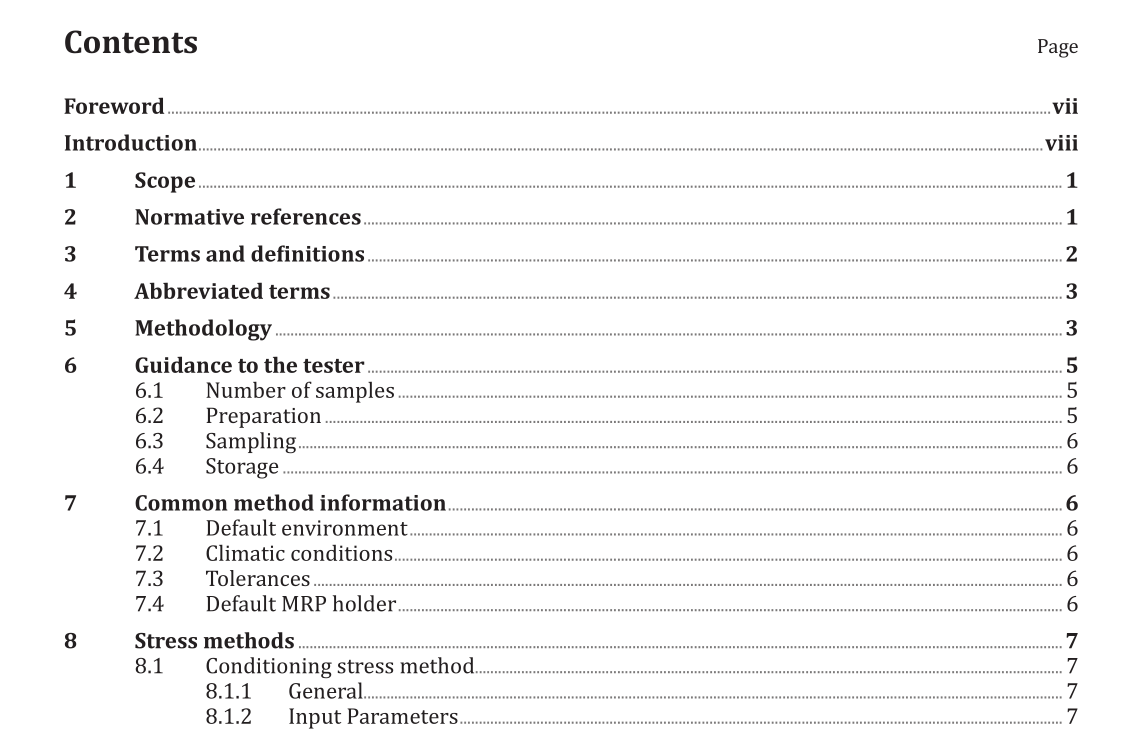

ISO IEC 18745-1 pdf download.Test methods for machine readable travel documents (MRTD) and associated devices

1 Scope

This document provides a set of instructions for evaluation of MRPs which may incorporate contactless integrated circuits. This evaluation is an instrument to establish the ability in principle of a specific type of document to fulfil the requirements of use. It supplies a structured approach to evaluate MRPs by: — defining reproducible stress methods to submit the document(s) under evaluation to specific stress or environmental conditions; — defining reproducible evaluation methods to measure numerical values for specific document properties; — defining test sequences that specify the order in which stress methods and evaluation methods are to be performed; — defining test plans to link specific user requirements to test sequences and related parameters. It specifies the minimum criteria to be achieved in order to meet ICAO’s expectations for durability of fully personalized MRPs.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: — IEC Electropedia: available at http: //www .electropedia .org/ — ISO Online browsing platform: available at https: //www .iso .org/obp 3.1 chip sheet sheet containing a chip 3.2 constant fixed values that can be given to parameters (within methods) when defining a sequence or test plan 3.3 evaluation method method to measure numerical values for specific document properties 3.4 evaluation result all numerical values related to document properties measured upon performing a test sequence 3.5 method instruction or set of instructions defining equipment and related tools and materials in an experimental setup, including general advice on their use in a specific test procedure 3.6 page any single side of an individual sheet of the MRP 3.7 parameter variable quantity within a test procedure that is not part of the instructions describing the procedure; in particular, experimental parameters that need to be controlled during the test sequence but whose values and/or tolerances are not explicitly defined in a specific stress or evaluation method or sequence 3.8 sheet any structure having a free edge and an opposite edge attached to the spine making up the MRP including covers, datapage, visa pages, observation pages and chip sheet Note 1 to entry: Each sheet has two pages. 3.9 stress method experimental setup and procedure that may or may not deteriorate or destroy the document under examination 3.10 test instruction distinct piece of information required within the framework of test execution 3.11 test plan list of test sequences and their specific test parameters and expected evaluation results 3.12 test procedure set of instructions to be followed in order to obtain a test result 3.13 test sequence test procedure that comprises a number of different methods in a defined order of execution 3.14 type evaluation type approval process of testing a design (type of documents produced while using a common material and component basis and the same manufacturing processes, including same production quality assurance process) to ensure it is compliant-in-principle with the specifications

6 Guidance to the tester

6.1 Number of samples References are given to a single MRP. However, multiple MRP samples may be tested simultaneously depending on the size and construction of the test apparatus. 6.2 Preparation Test samples shall be either finished MRPs or be prepared from finished MRPs having passed the entire production process including visual personalization with a dataset considered typical for the specific type of passport. Initialisation and personalization of the chip may be done in an arbitrary way as long as the chip is able to support the necessary tests within the intended test sequence. MRPs shall be conditioned in accordance with 7.1. Test pieces shall, as necessary, be prepared from the test samples in the particular form required by the test apparatus used.

ISO IEC 18745-1 pdf download