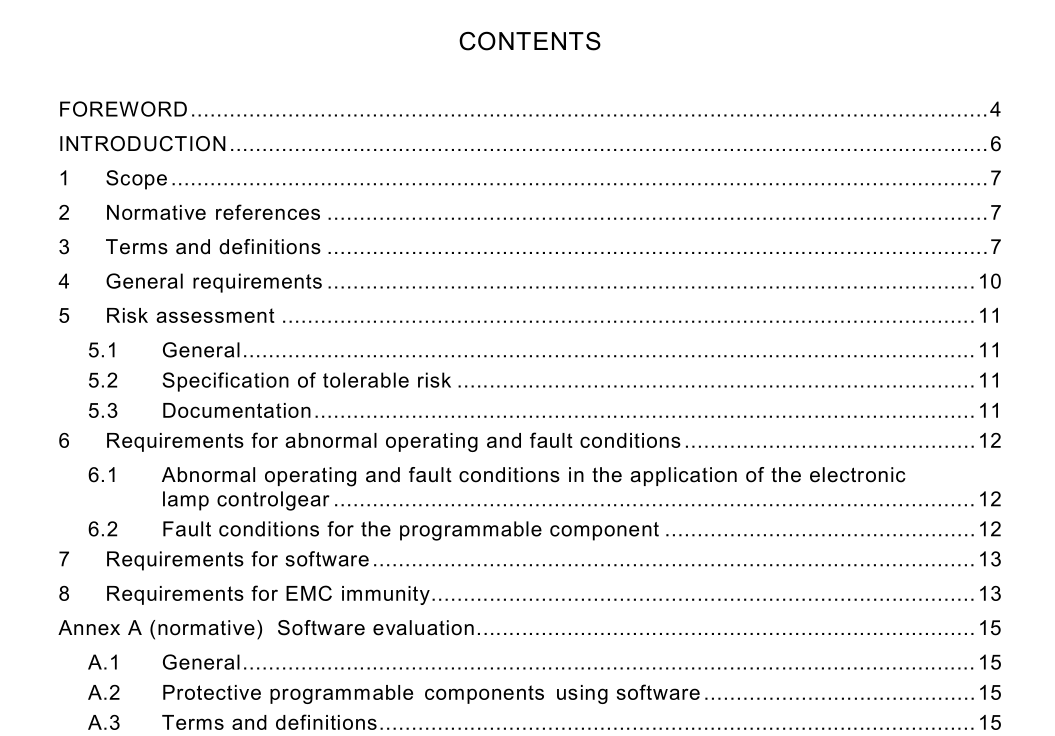

IEC 62733 pdf download.Programmable components in electronic lamp controlgear – General and safety requirements

1 Scope

This International Standard provides general and safety requirements for programmable components used in products covered by IEC 61 347. The requirements of this standard are only applicable to the programmable components (including its embedded software) in the electronic lamp controlgear. For other electric/electronic circuits and their components in the electronic lamp controlgear, the requirements of IEC 61 347 series apply.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. IEC 61 000-4-1 3:2002, Electromagnetic compatibility (EMC) – Part 4-13: Testing and measurement techniques – Harmonics and interharmonics including mains signalling at a.c. power port, low frequency immunity tests IEC 61 000-4-1 3:2002/AMD 1 :2009 IEC 61 347-1 , Lamp controlgear – Part 1: General and safety requirements IEC 61 347-2 (all parts) 1 , Lamp controlgear – Part 2: Particular requirements IEC 61 547:2009, Equipment for general lighting purposes – EMC immunity requirements IEC 61 508-4:201 0, Functional safety of electrical/electronic/programmable electronic safety- related systems – Part 4: Definitions and abbreviations IEC 61 508-5:201 0, Functional safety of electrical/electronic/programmable electronic safety- related systems – Part 5: Examples of methods for the determination of safety integrity levels IEC 61 508-7:201 0, Functional safety of electrical/electronic/programmable electronic safety- related systems – Part 7: Overview of techniques and measures

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. 3.1 central processing unit CPU part of a computing and controlling system that interprets and executes instructions Note 1 to entry: This note applies to the French language only. 3.2 programmable component based on computer technology which comprised of hardware, software, and of input and/or output units EXAMPLE The following are all programmable components: – microprocessors; – micro-controllers; – programmable controllers; – application specific digital integrated circuits (ASICs with programmable part); – programmable logic controllers (PLCs); – other computer-based devices (for example smart sensors, transmitters, actuators). Note 1 to entry: This term covers microelectronic devices based on one or more central processing units (CPUs) together with associated memories, etc. Note 2 to entry: The term programmable component is from ANSI/UL1 998:201 0, definition 2.39 [2].The definition in ANSI/UL for programmable component is: “Any microelectronic hardware that can be programmed in the design centre, the factory, or in the field. Here the term ‘programmable’ is taken to be ‘any manner in which one can alter the software wherein the behaviour of the component can be altered.” This term covers microelectronic devices based on one or more central processing units (CPUs) together with associated memories, etc. [SOURCE: IEC 61 508-4:201 0, 3.2.1 2, modified — “Programmable electronic” is replaced by “programmable component” which better describes that it is only a part of the controlgear.] 3.3 protective programmable component PPC programmable component that prevents a hazardous situation under abnormal operating conditions, or programmable component for which none of the output signals can lead to a hazardous situation Note 1 to entry: This note applies to the French language only. 3.4 software intellectual creation comprising the programs, procedures, data, rules and any associated documentation pertaining to the operation of a data processing system [SOURCE: IEC 61 508-4:201 0, 3.2.5, modified — The notes to entry are deleted.]3.8 single fault condition fault condition under normal operating condition of a single component or a device [SOURCE: IEC 62368-1 :201 0, 3.3.7.1 0, modified] 3.9 normal operating mode of operation that represents as closely as possible the most severe conditions of normal use that can reasonably be expected [SOURCE: IEC 62368-1 :201 0, 3.3.7.4, modified] 3.1 0 abnormal operating temporary operating condition that is not a normal operating condition and is not a single fault condition of the equipment itself Note 1 to entry: An abnormal operating condition may be introduced by the equipment or by a person . Note 2 to entry: The equipment, installation, instructions, and specifications should be examined to determine those abnormal operating conditions that might reasonably be expected to occur. Note 3 to entry: Faults that are the direct consequence of the abnormal operating condition are deemed to be a single fault condition. [SOURCE: IEC 62368-1 :201 0, 3.3.7.1 , modified] 3.1 1 fault tree analysis FTA top down, deductive failure analysis method in which a hazardous or serious event is analyzed using Boolean logic to combine a series of events causing this event Note 1 to entry: The FTA technique represents a ‘top-down’ analysis technique. Annex B of IEC 61 508-7:201 0 provides information for the minimum setup for an FTA report.

IEC 62733 pdf download