ASME Y14-6:2001 pdf download SCREW THREAD REPRESENTATION

3.2.1 On drawings with threaded parts, for standard series screw threads, the designation of the screw thread is noted and optionally supplemented by the pitch diameter and its tolerance, or pitch diameter limits.

3.2.1.1 For 60 deg inch threads, the thread designa- tion should include, in sequence, the nominal diameter in inches, the number of threads per inch, the letter symbol of the thread series, the number and letter of the thread class, and any qualifying information. For multiple start threads, replace the number of threads per inch with pitch in inches (P), lead in inches (L), and the number of starts in parentheses. An alternate designation method for multiple start threads retains the number of threads (pitches) per inch and adds lead in inches (L) and number of starts in parentheses following it.

For 60 deg metric threads, the thread designation should include in sequence, the metric thread/form identifier (M or MJ), the nominal diameter in millime- ters, a lowercase “x,” the pitch in millimeters [or for multiple start threads, L (lead in millimeters), P (pitch in millimeters), and number of starts in parentheses], pitch diameter tolerance symbol, crest diameter tolerance symbol (if different from that of the pitch diameter), and any qualifying information.

The thread length, the hole size, and the chamfer or countersink may be included in the note or dimen- sioned on the drawing of the part. Thread gaging system may be added to the thread designation in parentheses, or otherwise included in a drawing note. Acceptability of screw threads shown on a drawing shall be in accordance with the designated system, in accordance with ASME B1.3M.

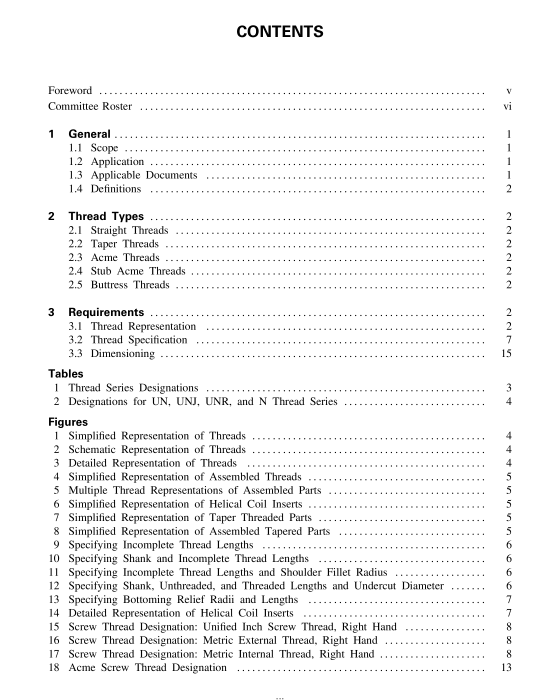

3.2.1.2 In general practice, the general designation and any diameter limits are in note form and referred to the drawing of the thread with a leader line. Figures 15 through 17 illustrate and explain the elements of designation of screw threads. NOTES (for metric thread designations):

(a) When transmitting a thread designation, where only capital letters are available, the external or internal thread may need further identification. Thus, the tolerance class identification is followed by the abbreviations EXT or INT in capital letters (e.g., M6X1-4G6G EXT or M6X1-6H INT).

(b) When indicating fit between threads, specify in the thread designation, the internal and external thread classes separated by a slash (e.g., MJ6x1-4H5H/4h6h).

(c) Where the pitch and crest diameter tolerance symbols are identical, the symbol need only be given once (e.g., M20x2.5-6H, with “6H” representing the pitch and minor diameter tolerance class symbols).

3.2.1.3 The nominal thread size is the basic major diameter and is specified as the fractional diameter, screw number, or its decimal equivalent. Where decimal equivalents are used for size callout, they shall be shown in four-place decimals (omitting zero in the fourth place) for fractional sizes, and in three-place decimals for number sizes. Examples are as follows:

1.000-8 UNC-2A

.5625–20 UNS-2A

1 1 ⁄ 4 -8 UN-2A

Numbered sizes may be shown because of established practices. The decimal equivalent, to three decimal places, should be shown in parentheses. Examples are as follows:

Nominal metric size or pitch should include zero before the decimal of values less than 1, and should not include any zeros beyond the last numbered decimal places (e.g., M8x1.5 or MJ2.5×0.45).

3.2.1.4 The series symbols and the class symbols identify the controlling thread standard and define the details of thread design, dimensions, and tolerances not specifically covered on the drawing. Series, class, and dimensional letters in a thread designation have the significance shown in Tables 1 and 2 as follows:

N National

O Outlet, Objective

P Pipe, Pitch

R Railing, Rounded root radius

RH Right hand

S Straight

SE Special engagement

SPL Special

T Taper

UN Unified

ASME Y14-6:2001 pdf download