ASME B89.4.23:2020 pdf download X-Ray Computed Tomography (CT) Performance Evaluation

5.5 Operating Procedures

When the test is performed, the CT system shall be operated according to the manufacturer’s operating manual. The instructions in the operatingmanual are considered partofthe rated conditions; i.e., theyare required to be satisfied for the MPE value to be valid. Specific operating procedures may include, but are not limited to, the following:

(a) start-up and stability evaluation of the X-ray source.

(b) qualification and correction of the X-ray detector.

(c) estimation and assessment of the CT geometry.

(d) thermal stabilization of the machine prior to data collection.

(e) technique-development requirements (penetration,contrast, noise,geometric unsharpness) These requirementsare not operator competency requirements and may be individually specified.

In addition,theCT’ system manufacturer shall specify any required information that the operator mustsupply as aratedcondition,e.g.. the CTE of the test object.

5.6 Test-Object Material

The material properties of the object under measurement are considered rated operating conditions.Material con-ditions are subdivided into the following three classes:

(a) plastic

(b) aluminumc) steel

Each class is defined in Mandatory Appendix l, which provides a detailed description of the allowed polymers or alloyswithin each class.

5.7 Maximum Loading

The maximum loading mass that can be on the CT system during a measurement shall be specified as a rated condition.TheCT system manufacturer may specify a maximum load per unit area (in kilograms persquare centimeter) in additionto the maximum load.

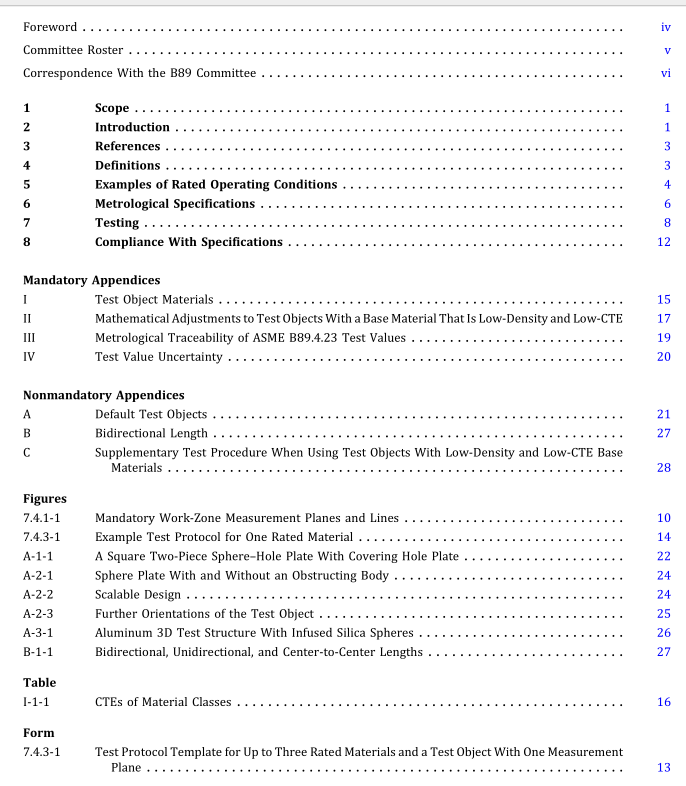

6 METROLOGICAL SPECIFICATIONS

This Standard describes the following metrological specifications:(a) center-to-center length error

b] sphere size error

c) sphere form error

Because the absorption ofX-rays by material is a significant influence quantity, the CTsystem manufacturer shallstatethe MPE for each measurand, for each standardized material class (plastic, aluminum, and steel, as described inMandatory Appendix l).The MPE specifications may differ for each of the materials the CT’ system is designed tomeasure; i.e., the MPEs for plastic may differ from those for aluminum, which may differ from those for steel lfthe system is designed to measure only one material, e.g, plastic workpieces, then the CT’ system manufacturershall specify the MPEs for that material.

The MPE specifications may be specific to measurement conditions such as the work zone (see para. 5.4), providedthese are within the rated conditions of the CT system as stated by the CT system manufacturer.A CT system shall be inconformance with theMPEspecification if, when tested by a properly trained user, it generates no errors in measurement(of length, diameter, or form)greater than the MPEvalue (evaluated at the measurement conditions).A properly traineduser is a user who is capable of selecting the CT’ system parameters(e.g,voltage, current, spot size) according to the CTsystem manufacturer’s operating procedures.

TheCTsystem manufactureris free to choose any specification format(table, formula, etc.) for stating the MPEs that areapplicable within the range of rated conditions for the measurands identified in this Standard.MPE specifications mayinclude MPEs for measurements taken at subranges of the rated conditions,e.g,for workzones that vary in size based onCT geometry, detector cropping, and region of interest.

The workzone may be affected bytheCT scanning mode.For example, helicalscanning mode may provide an elongatedwork-zone cylinder.TheCT system manufacturer shall provide an MPEfor a workzone that, regardless of scanning mode,is compatible with test objects specified by this Standard (see section 7 and Nonmandatory Appendix A).

MPEspecifications and correspondingtest value symbols shall have a “CAD” (computer-aided design) designation,e.g,P size.sphalLAD,CT,MPr and Psirze.sph.allcAD.cT if preknowledge (see section 4) is used in any way prior to or during CT scanacquisition, radiograph processing (e.g, filtering), volume reconstruction, surface determination, or any surface-pointprocessing (e.g., filtering). See para. 7.3 for requirements for the use of preknowledge during testing.

For each individual scan, the same CT system settings (software fltering, reconstruction,surface algorithm, etc.) shallbe used to produce the surface points and to evaluate the measurands (length, size, and form).

All spheres used as metrological geometric elements shall have a minimum diameter specified in voxels by the manu-facturer in the rated conditions. No sphere shall exceed 51 mm in diameter, which is the same maximum used in ISO10360-5,ISO 10360-7,and lso 10360-9.

ASME B89.4.23:2020 pdf download