ASME B107.100:2020 pdf download Flat Wrenches

1 scOPE

This Standard provides performance and safety re-quirements for combination, open end, box, and flarenut wrenches; open end adjustable wrenches, withrack and worm adjustment, generally used on both hexa-gonal and square fasteners; crowfoot wrenches having awrench component of the open end type or flare nut type;and ratcheting box wrenches used in hexagonal (6-point),double-hexagonal ( 12-point), square (4-point), anddouble-square (8-point) wrenching applications.Thetools covered herein are listed by Category number inTable 4-1.

Inclusion of dimensional data in this Standard is notintended to imply that all of the products describedherein are stock production sizes.Manufacturers maymake sizes not listed in this Standard. Consumers arerequested to consult with manufacturers concerninglists of stock production sizes.

2 DEFINITIONS

adjusting worm: portion of the wrench used to adjust theclearance between the fixed and movable jaws.

angle wrench: a wrench with one end having an angle over55 deg.

box wrench: wrench with an enclosed opening that gripsall faces of the fastener.

combination wrench: a wrenen t. ..box on the other.

engineer’s wrench: in this Standard, a wrench that is openon one end, different size open on the other.

NOTE: Industry may refer to single-ended open end wrenches asengineer’s wrenches.

fixed jaw: portion of the frame that contacts the fastener.flare nut wrench: wrench that is used for gripping the nutson the ends of tubes, with a slotted box end.

frame: portion of the wrench containing the fixed jaw andhandle.

handle: portion of the wrene wrench..ignition wrench: a thin angle wrench.

movable jaw: movable portion of an adjustable wrencnthat contacts the fastener.

offset: pitch, or rotation around a transverse horizontalaxis.

open end wrench: wrench with a U-shaped opening thatgrips two opposite faces of a fastener. The other end maybe another open end or a nonwrenching end (handle).proof torque: predetermined test torque to which a sampleis subjected.

reversing lever: device to control the reversingmechanism.

reversing torque: force to rotate the wrench in the ratch-eting or nonloading direction.

shifter: device to control the reversing mechanism.

slotted box: box wrench end with an opening smaller thanthe width across flats. See also flare nut wrench.

tappet wrench: open end wrench where the head oropening is thinner than standard wrenches to allow clear-ance to adjust valve trains.

worm pin: pin used to retain the adjusting worm in theframe.

worm spring: spring used to induce friction between theframe and adjusting worm for holding the adjusting wormin any preset position.

3 REFERENCES

The following is a list of publications referenced in thisStandard. The latest available edition shall be used.ASMEB107.4, Driving and Spindle Ends for Portable Hand,Impact,Air, and Electric Tools (Percussion ToolsExcluded)

ASME B107.17,Gages and Mandrels for Wrench OpeningsPublisher: The American Society of Mechanical Engineers(ASME), Two Park Avenue,New York, NY 10016-5990(www.asme.org)

ASTM B117,Standard Practice for Operating Salt Spray(Fog) Apparatus

ASTM B537,Standard Practice for Rating of ElectroplatedPanels Subjected to Atmospheric Exposure

ASTM B571,Standard Practice for Qualitative AdhesionTesting of Metallic Coatings

ASTM D968, Standard Test Methods for Abrasion Resis-tance of Organic Coatings by Falling Abrasive

ASTM E18,Standard Test Methods for Rockwell Hardnessand Rockwell Superficial Hardness of Metallic MaterialsASTM E92,Standard Test Method for Vickers Hardness ofMetallic Materials

Publisher: American Society for Testing and Materials(ASTM International),100 Barr Harbor Drive, P.O.Box C700,West Conshohocken,PA 19428-2959( www.astm.org)

SAE J1703,Motor Vehicle Brake Fluid

Publisher: SAE International,400 Commonwealth Drive,

Warrendale,PA 15096-0001 (www.sae.org)

Guide to Hand Tools —Selection, Safety Tips, Proper Useand Care

Publisher: Hand Tools Institute (HTI),25 North Broadway,Tarrytown,NY 10591 (www.hti.org)

4 CLASSIFICATION

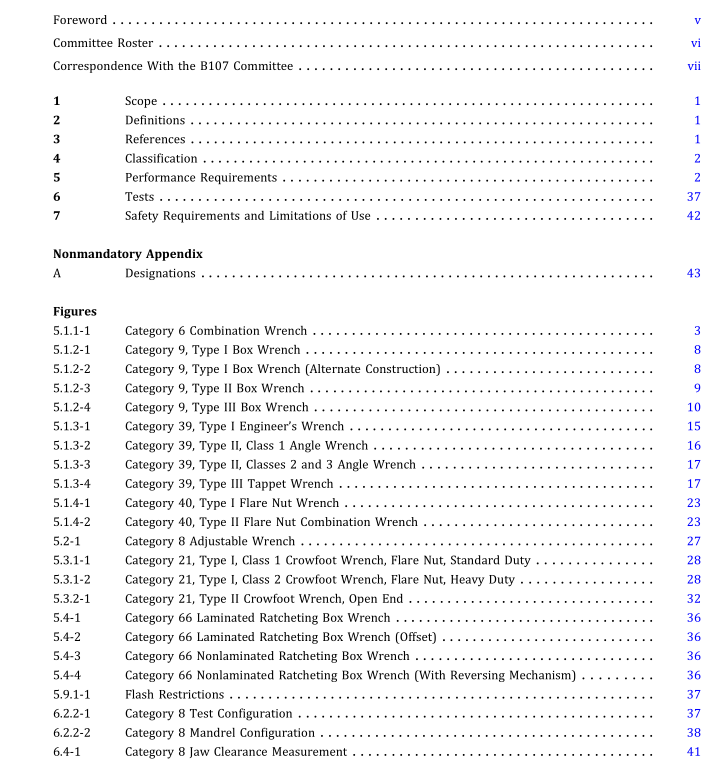

Categories,Types,and Classes of flat wrenches areshown in Table 4-1 and the applicable figures indicatedtherein.

5 PERFORMANCE REQUIREMENTS

The illustrations shown herein are descriptive and notrestrictive; they are not intended to preclude the manu-facture of wrenches that are otherwise in accordance withthis Standard.

Wrenches shall provide a well-proportioned comfor-table handgrip and be similar to the figure to which refer-ence is made.The engaging surfaces of the wrench

ASME B107.100:2020 pdf download