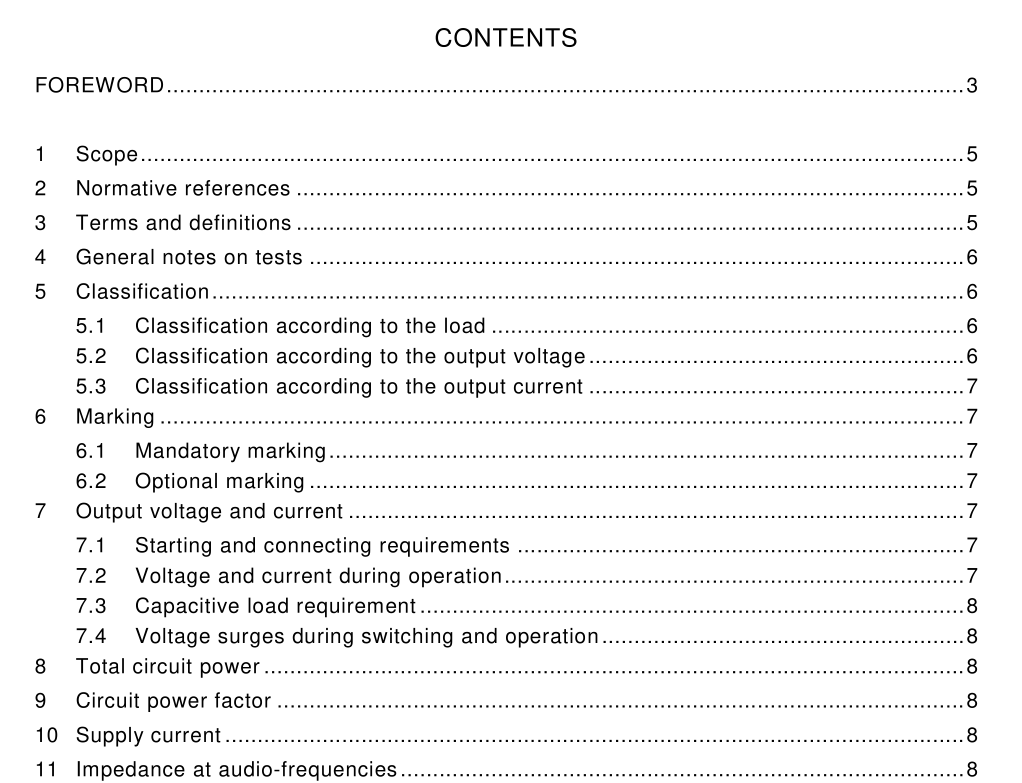

IEC 62384 pdf download.DC or AC supplied electronic control gear for LED modules – Performance requirements

1 Scope

This international standard specifies performance requirements for electronic control gear for use on d.c. supplies up to 250 V and a.c. supplies up to 1 000 V at 50 Hz or 60 Hz with an output frequency which can deviate from the supply frequency, associated with LED modules according to IEC 62031 . Control gear for LED modules specified in this standard are designed to provide constant voltage or current. Deviations from the pure voltage and current types do not exclude the gear from this standard. NOTE 1 The tests in this standard are type tests. Requirements for testing individual control gear during production are not included. NOTE 2 Requirements for control gear which incorporate means for varying the output power are under consideration. NOTE 3 It may be expected that control gear complying with this standard will ensure satisfactory operation between 92 % and 1 06 % of the rated supply voltage, taking into account the specifications of the LED module manufacturer.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. 3.1 total circuit power total power dissipated by control gear and LED module(s) in combination, at rated supply voltage of the control gear and at the highest rated output load. 3.2 circuit power factor λ ratio of the measured circuit power to the product of the supply voltage (r.m.s.) and the supply current (r.m.s.). 3.3 high audio-frequency impedance control gear control gear the impedance of which in the frequency range 250 Hz to 2 000 Hz exceeds the values specified in Clause 1 1 of this standard.

4 General notes on tests

4.1 The tests according to this standard are type tests. NOTE The requirements and tolerances permitted by this standard are based on testing of a type test sample submitted by the manufacturer for that purpose. In principle this type test sample should consist of units having characteristics typical of the manufacturer’s production and be as close to the production centre point values as possible. It may be expected with the tolerances given in the standard that products manufactured in accordance with the type test sample will comply with the standard for the majority of the production. Due to the production spread however, it is inevitable that there will sometimes be products outside the specified tolerances. For guidance of sampling plans and procedures for inspection by attributes, see IEC 6041 0. 4.2 For tests which are carried out with a LED module or LED modules, this (these) LED module(s) shall fulfil the following requirements: The wattage of the LED module(s) when measured at its(their) rated voltage or rated current (d.c. and/or a.c.) shall not differ from the rated wattage by more than +6 % and –0 %. 4.3 The tests shall be carried out in the order of the clauses, unless otherwise specified. 4.4 One specimen shall be submitted to all the tests. 4.5 In general all the tests are made on each type of control gear or, where a range of similar control gear is involved for each rated wattage in the range or on a representative selection from the range as agreed with the manufacturer. 4.6 The tests shall be made under the conditions specified in Clause A.1 . Since up to now data of LED modules are not published in an IEC standard, they shall be made available by the LED module manufacturer. 4.7 All control gear covered by this standard shall comply with the requirements of IEC 61 347-2-1 3. 4.8 The tests shall be carried out with the length of the output cable of both 20 cm and 200 cm unless otherwise declared by the manufacturer.

IEC 62384 pdf download