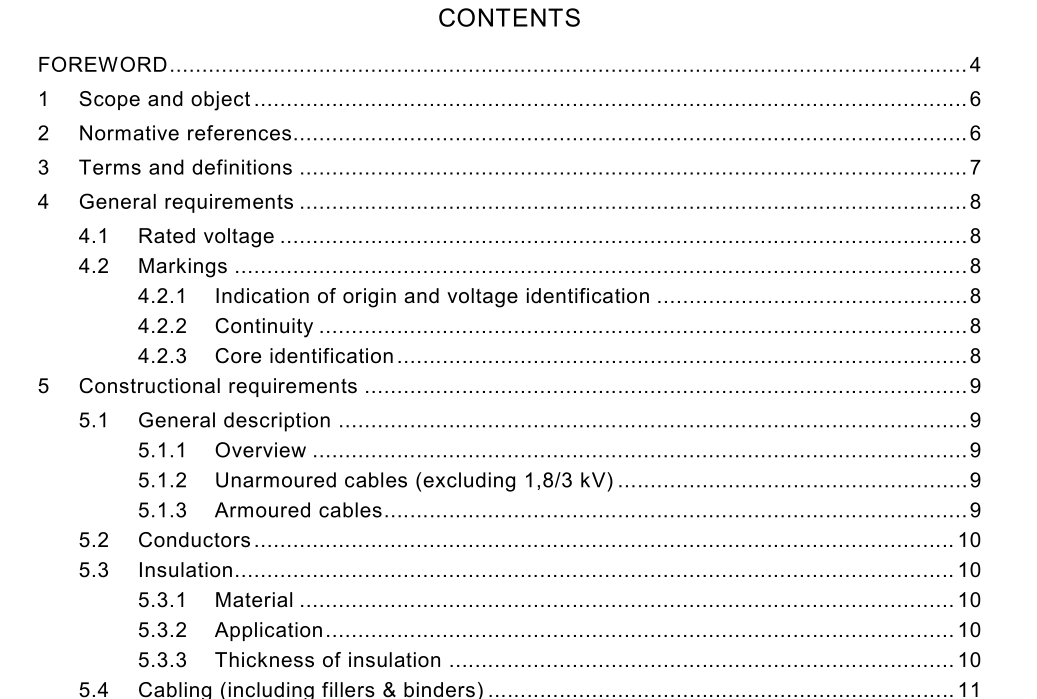

IEC 60092-353 pdf download.Electrical installations in ships – Part 353: Power cables for rated voltages 1 kV and 3 kV

1 Scope and object

This part of the IEC 60092 series is applicable to shipboard and offshore non radial field power cables with extruded solid insulation, having a voltage rating of 0,6/1 (1 ,2) kV and 1 ,8/3 (3,6) kV intended for fixed installations. Cables for use in circuits requiring resistance to fire are included. The various types of power cables are given in 5.1 . The constructional requirements and test methods shall comply with those indicated in IEC 60092-350, unless otherwise specified in this standard. The object of this standard is: – to standardize cables whose safety and reliability is ensured when they are installed in accordance with the requirements of IEC 60092-352 or IEC 61 892-4; – to lay down standard manufacturing requirements and characteristics of such cables directly or indirectly bearing on safety; – to specify test methods for checking conformity with those requirements.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60092-350 as well as in IEC 60050-461 apply.

5 Constructional requirements

5.1 General description 5.1 .1 Overview Shipboard and offshore cables for fixed installations shall be single or multicore cables generally constructed as follows: 5.1 .2 Unarmoured cables (excluding 1,8/3 kV) a) Single-core unarmoured unsheathed cable • copper conductor, see 5.2; • insulation applied as a single layer of insulating compound of one of the types described in 5.3 with an enhanced thickness equivalent to that of a combined insulation and outer sheath for use in unarmoured cables installed in an adequately protected environment (see 5.3.3 for the thickness). b) Unarmoured single- or double-sheathed cable • copper conductor, see 5.2; • insulation, see 5.3; • cabling (for multicore cables), see 5.4; • inner covering (optional, but mandatory when a braided or a metal tape electrostatic screening is applied over the core lay-up), see 5.5; • electrostatic screening (optional), see 5.6; • inner sheath (optional), see 5.7; • outer sheath applied as either one or two layer systems, see 5.9. 5.1 .3 Armoured cables a) Armoured single-sheathed cable with outer sheath only • copper conductor, see 5.2; • insulation, see 5.3; • cabling (for multicore cables), see 5.4; • inner covering below electrostatic screening (optional, but mandatory when a braided or a metal tape electrostatic screening is applied over the core lay-up), see 5.5; • electrostatic screening (optional), see 5.6; • inner covering (optional, but mandatory in case of a braid armour of galvanised steel wires in which case the inner covering shall be extruded), see 5.5; • braid armour, see 5.8; • outer sheath applied as either one or two layer systems, see 5.9. b) Armoured double-sheathed cable with inner and outer sheath • copper conductor, see 5.2; • insulation, see 5.3; • cabling (for multicore cables), see 5.4;• inner covering (optional, but mandatory when a braided or a metal tape electrostatic screening is applied over the core lay-up), see 5.5; • electrostatic screening (optional), see 5.6; • inner sheath, see 5.7; • braid armour, see 5.8; • outer sheath applied as either one or two layer systems, see 5.9. NOTE The use of a thermoplastic inner sheath (ST2 or SHF1 ) is not recommended if the outer sheath consists of an elastomeric crosslinked material. c) Armoured single-sheathed cable with inner sheath only • copper conductor, see 5.2; • insulation, see 5.3; • cabling (for multicore cables), see 5.4; • inner covering (optional, but mandatory when a braided or a metal tape electrostatic screening is applied over the core lay-up), see 5.5; • electrostatic screening (optional), see 5.6; • inner sheath, see 5.7; • braid armour, see 5.8. NOTE Cables for installation in spaces where corrosion may occur, for example weather decks, wet locations, battery compartments, refrigeration rooms, etc., should have an outer sheath over the braid, if any, unless the braid itself is corrosion-resistant. 5.2 Conductors Material, metal coating, class and form of the conductors shall be in accordance with IEC 60092-350. For cables having rated voltage 1 ,8/3 kV only circular stranded compacted or non-compacted conductors with a minimum cross-section of 1 0 mm² are permitted. A separator between conductors and insulation is permitted. 5.3 Insulation 5.3.1 Material The insulating compounds and their designations shall be as given in IEC 60092-351 thus: – for 0,6/1 (1 ,2) kV cables, types EPR, HEPR, XLPE, HF 90 or S 95 shall be used; – for 1 ,8/3 (3,6) kV cables, types only EPR, HEPR, XLPE shall be used. The insulation system shall consist of one of the options (a) to (d) as listed in IEC 60092-350, 4.3.1 . 5.3.2 Application The application shall be as detailed in IEC 60092-350, 4.3.2.

IEC 60092-353 pdf download