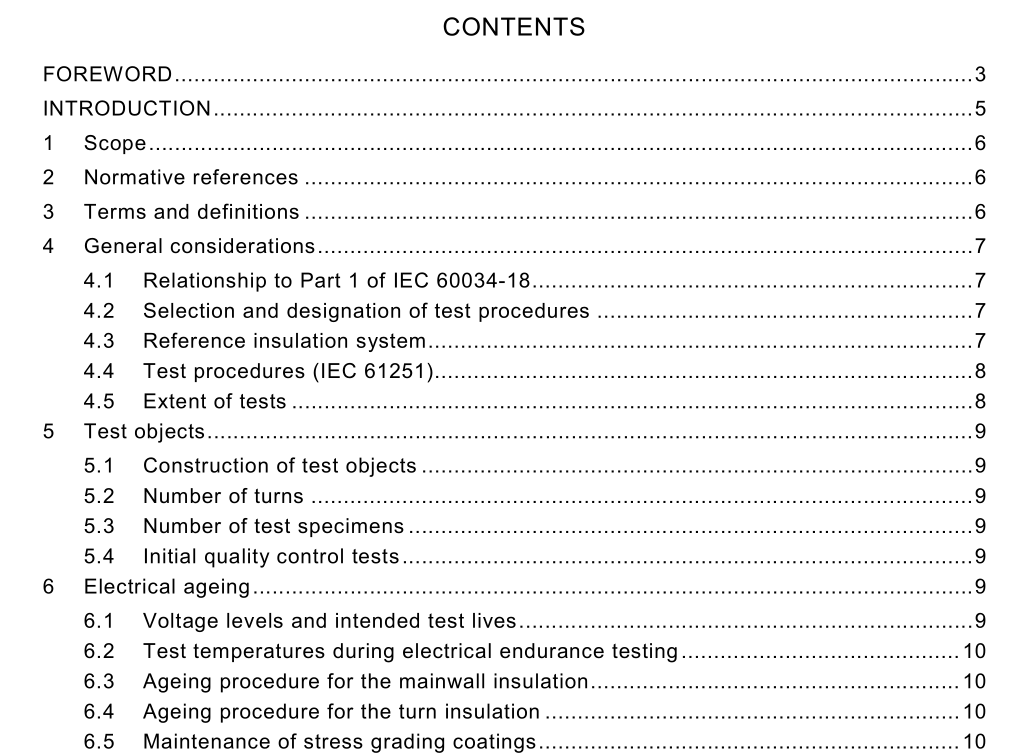

IEC 60034-18-32 pdf download.Rotating electrical machines – Part 18-32: Functional evaluation of insulation systems – Test procedures for form-wound windings – Evaluation by electrical endurance

1 Scope

This part of IEC 60034-1 8 describes test procedures for the evaluation of electrical endurance of insulation systems for use in a.c. or d.c. rotating electrical machines using form-wound windings. The test procedures are comparative in nature, such that the performance of a candidate insulation system is compared to that of a reference insulation system with proven service experience. The test procedures are principally directed at the insulation systems in air-cooled machines but may also be used for evaluating parts of the insulation systems in hydrogen cooled machines. Note that the qualification procedures of inverter duty insulation systems for form-wound windings can be found in IEC 60034-1 8-42.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. 3.1 mainwall insulation main electrical insulation that separates the conductors from the earthed stator/rotor core in motor and generator windings 3.2 turn insulation electrical insulation that covers each conductor in coils/bars 3.3 interturn insulation electrical insulation that separates the conductor turns from each other in coils/bars 3.4 corona protection material material which is used to coat a stator coil/bar within the slot portion of the stator core to avoid slot discharges 3.5 stress grading material material generally having a non-linear resistivity characteristic, applied to the endwindings of stators to reduce the maximum surface electrical stress

4 General considerations

4.1 Relationship to Part 1 of IEC 60034-1 8 The principles of Part 1 of IEC 60034-1 8 should be followed unless the recommendations of this International Standard indicate otherwise. 4.2 Selection and designation of test procedures One or more of the procedures in this International Standard should be suitable for the majority of evaluations. Evaluation is usually performed by the manufacturer of the machine/coils or by a third party laboratory. It is the manufacturer’s responsibility to justify the most suitable procedure in Table 1 on the basis of past experience and knowledge of the insulation systems to be compared. The test procedure should be selected from Table 1 and designated by IEC 60034-1 8-32 procedure N, where N is the designation given in the Table 1 . Subclauses 4.3, 4.4 and 4.5 give guidance on how to select the test procedure.All the above tests are carried out at room temperature. However, if they are to be performed at any other temperature (see 6.2.2), the designation of the test procedure shall include the Celsius temperature in brackets, e.g. AA(1 90). Each of the procedures may be used for the full evaluation according to 4.5.1 or for the reduced evaluation according to 4.5.2. Procedure AA is the preferred choice if the manufacturer has no past experience or knowledge of the candidate system and the behaviour of the mainwall insulation is defined. 4.3 Reference insulation system A reference insulation system should be tested using a test procedure equivalent to that used for the candidate system (see IEC 60034-1 8-1 ). The reference insulation system should have service experience at not less than 75 % of the intended maximum rated voltage of the candidate system. When extrapolation of the insulation thickness is used, some information should be provided showing the correlation between electrical lifetime and electrical stress for the different insulation thicknesses.4.4 Test procedures (IEC 61251) 4.4.1 General Electrical ageing tests are usually performed at fixed voltage levels until failure. From such tests, characteristic times to failure at each voltage level are obtained. The results for both the candidate system and the reference system should be reported on a graph, as shown by the example in Figure 1 , and compared. There is no proven physical basis for extrapolation of this characteristic to the service voltage level U N / 3 , where U N is the r.m.s. rated phase to phase voltage. Statistical evaluation of the results of testing should be performed according to IEC 62539. 4.4.2 Electrical ageing of the mainwall insulation In service, electrical ageing of the mainwall insulation is primarily caused by continuous elec- trical stress at power frequency. In addition, the insulation is required to withstand transient over-voltages arising from switching surges or inverter supply. The ability of the mainwall insulation to withstand transient over-voltages from converter supplies may be demonstrated by the system’s performance using IEC 60034-1 8-42. This standard describes voltage ageing of the mainwall insulation, carried out at power frequency or at a frequency up to 1 0 times greater.

IEC 60034-18-32 pdf download