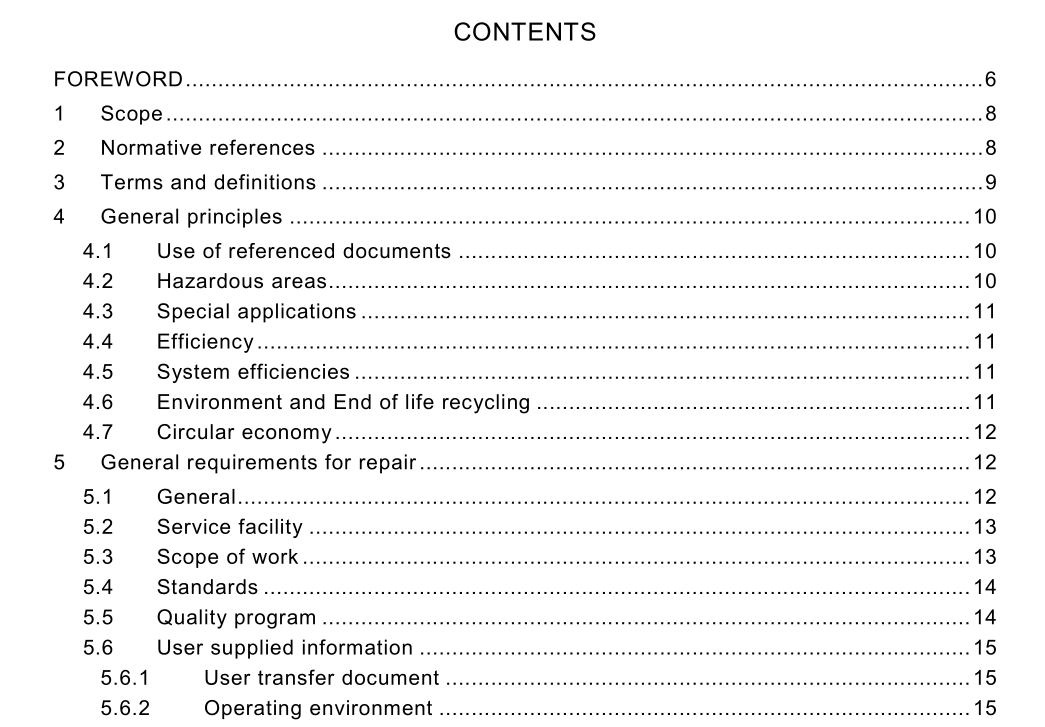

EN IEC 60034-23 pdf download.ROTATING ELECTRICAL MACHINES – Part 23: Repair, overhaul and reclamation

1 Scope

This part of IEC 60034 covers the procedures necessary to ensure the satisfactory repair, overhaul, and reclamation of all types and sizes of rotating electrical machines covered by the IEC 60034 series. The standard creates a generic industry procedure covering common aspects of a complete repair. The scope of work depends on the machine type, rating, condition, and the importance of plant reliability and safety. It includes • determining cause of failure, where necessary; • determining the extent of repair, as applicable; • defining revised performance, operating and ambient conditions, if required; • reviewing the original design, and upgrading the specification of the design, if required; • proving the quality and performance of the repaired machine, maintaining or improving the rated energy efficiency; • ensuring environmental considerations are taken into account. This document does not supersede the requirements prescribed in IEC 60079-1 9 or elsewhere concerning the repair and overhaul for machines used in explosive atmospheres. Machines for special applications such as hermetic, submersible, nuclear, hydrogen cooled machines, military, aviation and traction motors might have additional requirements, which are the subject of agreement between the service facility and user. This document is not intended to take the place of the original machine manufacturer’s instructions and recommendations. Re-designs and performance changes requiring machine designer input are beyond the scope of this document.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60034 (all parts) and the following apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: • IEC Electropedia: available at http://www.electropedia.org/ • ISO Online browsing platform: available at http://www.iso.org/obp 3.1 customer person or company, who places the order for a repair with the service facility and may or may not be the owner or user of the machine 3.2 dismantling disassembly of a machine into component parts or sub-assemblies 3.3 maintenance routine actions taken to preserve the installed equipment in a fully serviceable condition 3.4 manufacturer party responsible for the manufacture of the machine as originally supplied 3.5 overhaul action to restore to fully serviceable condition equipment which has been in use or in storage for a period of time but which is not faulty 3.6 reclamation means of repair involving the removal or addition of material to reclaim component parts which have sustained damage, in order to restore such parts to a serviceable condition in accordance with the original standards and specifications 3.7 refurbisher party responsible for the refurbishing work, its sub-contractors and suppliers 3.8 refurbishment total process of preparing a machine, no longer adequate for duty with normal maintenance, to make it suitable for further service 3.9 relevant standard standard to which the equipment was originally designed 3.1 0 repair action to restore faulty equipment to its fully serviceable condition complying with the relevant standard 3.1 1 repairer manufacturer, user, or a third party (repair agency) who carries out the repair of the equipment 3.1 2 rewinding part of the refurbishment related to removing and replacing some or all of the machine winding their insulation, connection and support systems 3.1 3 service facility manufacturer, user, or a third party (repair agency) providing a service that consists of the repair, overhaul, or reclamation of equipment 3.1 4 serviceable condition condition which permits parts or equipment to be used without prejudice to performance 3.1 5 user owner, or party arranging or requiring the repair

4 General principles

4.1 Use of referenced documents Older machines being repaired were designed to conform to earlier versions of the relevant standards applicable when they were manufactured. It is possible that they would not be able to meet the requirements of the latest standards. If this is the case the earlier standard should be referred to for the specifications that the machine was manufactured to. 4.2 Hazardous areas This document can be used in conjunction with IEC 60079-1 9, but does not supersede the requirements prescribed in the latest version of IEC 60079-1 9. Special restrictions apply including • the scope of repair allowed by machine certification, • individual personnel ‘Ex’ competency, • the specific design limitations of different protection concepts.

EN IEC 60034-23 pdf download