ASME B16.12:2009 pdf download Cast Iron Threaded Drainage Fittings

3 MARKING Each fitting shall be marked with the manufacturer’s name or trademark in accordance with the requirements of MSS Standard Practice No. SP-25.

4 MATERIALS

4.1 Castings The dimensions prescribed in this Standard (Tables 3 through 13) are based on gray iron castings of high quality produced under regular control of chemical and physical properties by a recognized process. The manu- facturer shall be prepared to certify that the product has been so produced and that its chemical and physical properties, as proved by test specimens, are equal to the requirements specified in ASTM A 126, Specification for GrayIronCastings for Valves, Flanges, and Pipe Fittings.

4.2 Optional Material Drainage fittings are regularly made of cast iron. At the option of the manufacturer, drainage fittings may be furnished of malleable iron complying with the mini- mum physical requirements of ASTM A 197, Specification for Cupola Malleable Iron.

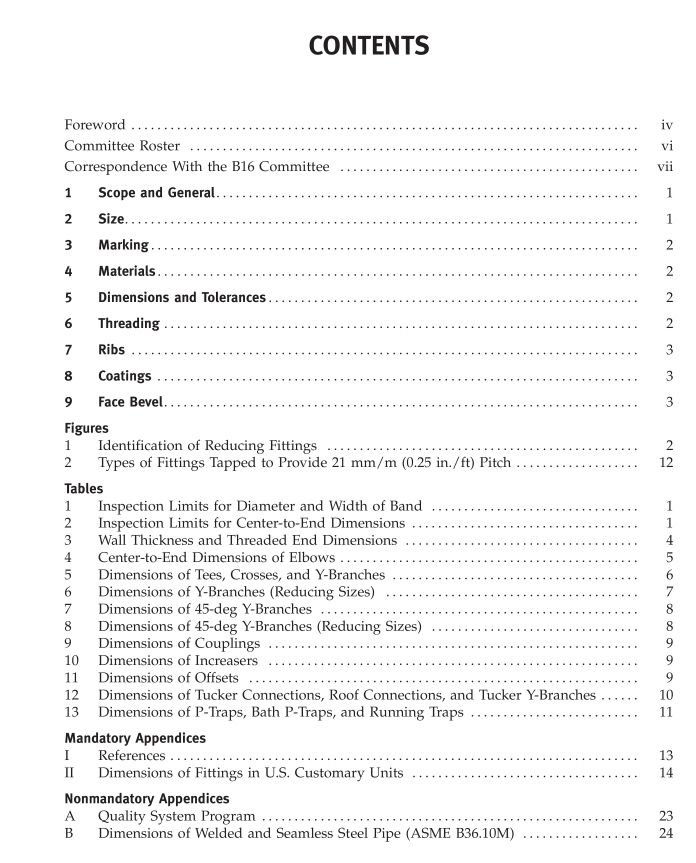

5 DIMENSIONS AND TOLERANCES

5.1 Dimensions Dimensions in SI (metric) units are given in Tables 3 through 13 for various types of fittings. Those dimen- sions are the standard. Corresponding U.S. Customary values are given in Tables II-3 through II-13 in Mandatory Appendix II. Some dimensions of steel pipe from ASME B36.10M are listed for convenience in Nonmandatory Appendix B in inches only. Tolerances applicable to dimensions of fittings are specified in paras.

5.2 through 5.6. 2 5.2 Metal Thickness At no point in the castings shall the metal thickness be less than 90% of the values listed in Table 3.

5.3 Thread Chamber The length of thread and total length of thread cham- ber to shoulder shall not vary from the dimensions shown in the tables by more than plus or minus the equivalent of the pitch of one thread.

5.4 Outside Diameter and Width of Band The minus tolerances given in Table 1 are permitted on inspection to apply to the diameter of the band and the width of the band.

5.5 Inside Diameter of Fitting The inside diameter shall not vary from dimensions shown by more than the following:

(a) for sizes 1 1 ⁄ 2 NPS 4, inclusive ±0.8 mm (0.03 in.)

(b) for sizes 5 NPS 8, inclusive ±1.6 mm (0.06 in.)

5.6 Center-to-End The center-to-end dimensions shall not vary from the given dimensions by more than the values given in Table 2.

5.7 Shoulder These fittings are provided with shoulders so that when used with Standard Wall Pipe (ASME B36.10M), the end of the pipe practically meets the shoulder as the joint is made up, thereby forming a smooth passageway.

6 THREADING

(a) All fittings (except roof connections) shall be threaded with American National Standard Taper Pipe Threads (ASME B1.20.1), and the variations in threading shall be limited to one turn small and no turn large. Threaded openings without shoulder, however, shall be limited to one turn large and one turn small from the gaging notch on the plug when using working gages. Roof connections may have taper threads as above or American National Standard StraightPipe Threads, Free Fitting Mechanical Joint NPSM (ASME B1.20.1).

(b) When gaging internal threads, the notch shall be flush with the bottom of the chamfer, which shall be considered as being the intersection of the chamfer cone and the pitch cone of the thread. This depth is approxi- mately equal to one-half thread from the face of the fitting.

(c) All threads shall be countersunk a distance not less than one-half thread at an angle approximately 45 deg with the axis of the thread, both for easier entrance in making a joint and for protection of the thread. Countersinking shall be concentric with the thread.

(d) The length of thread specified in this Standard shall be measured to include the countersink.

(e) The maximum allowable variation in the align- ment of threads of all openings of threaded fittings shall be 5 mm/m (0.06 in./ft).

ASME B16.12:2009 pdf download