ASME A112.14.3:2001 pdf download GREASE INTERCEPTORS

Combined Horizontal Waste Piping. The com- bined horizontal waste piping into which the sink outlets connect shall be installed with the center line 11 in. (0.28 m) below the bottom of the sink and properly hung and braced from the sink reinforcement and supports. This waste pipe shall be fitted to the inlet of a vented (air intake) flow control and/or vent or equal device (if required for use with the interceptor).

(c) Flow Control and/or Vent Device (Optional). The flow control and/or vent device shall be adequate in size for the interceptor to be tested and shall be equipped with the proper size orifice and/or other details to provide the proposed flow rate of the subject interceptor, based on the simultaneous drainage of both sink compartments as detailed hereinafter. The waste piping on either side of the flow control and/or vent shall be fitted with unions to permit removal of the device. (d) Vertical Waste Riser. The vertical waste riser shall be connected to the outlet of the flow control and/ or vent device and shall extend downward to connect to the grease interceptor inlet by means of an elbow and a short horizontal nipple.

(e) Interceptor Discharge. The discharge pipe from the interceptor outlet to the skimming tank shall have a minimum pitch of 1 ⁄ 8 in. per ft (1 cm per m) and shall be provided with a 2-in. (50 mm) vent properly located to prevent siphoning of the interceptor.

(f) Interceptor Connections. If the inlet and/or outlet openings of the interceptor to be tested exceed 2 in. (50 mm) or 3 in. (76 mm) for test flows exceeding 50 gpm (190 L/m) in size, reducing couplings shall be used to permit connections of the 2 in. (50 mm) or 3 in. (76 mm) for test flows exceeding 50 gpm (190 L/m), inlet and discharge pipes.

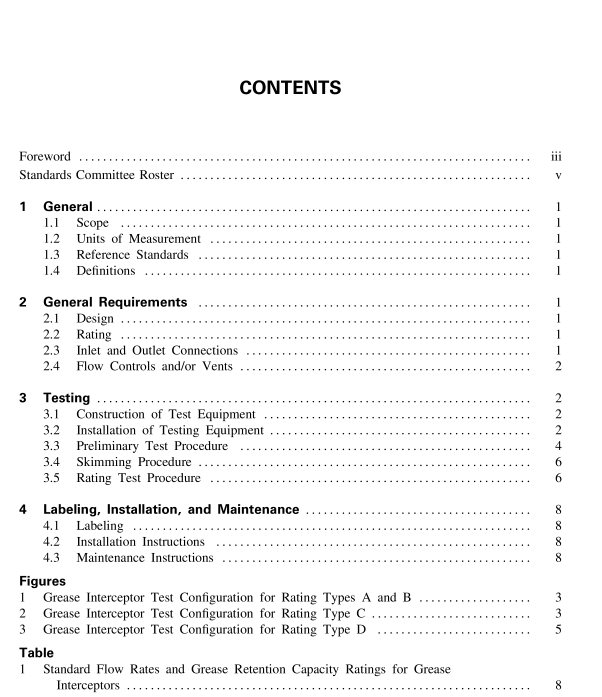

3.2.2 Indirect Connection Test Type D. See Fig. 3. 3.2.2.1 Sink and Interceptor Location. The sink shall be located on a floor with the sink rim 3 ft (0.91 m) above the floor level and 13 ft (3.96 m) above the outside bottom of the grease interceptor being tested.

3.2.2.2 Floor Sink and Location. A 6 in. (152 mm) deep floor sink to receive the indirect waste discharge from the test sink shall be located in the floor supporting the test sink. The rim of the floor sink shall be located at floor level. The outlet of the 4 floor sink shall be sized to handle the test flow rate, and shall be not less than 3 in. (76 mm). 3.2.2.3 Skimming Tank Location. The skim- ming tank shall be located low enough, with respect to the interceptor, for the discharge piping from the interceptor to clear the tank rim by not less than 3 in. (76 mm).

3.2.2.4 Installation of Waste Piping

(a) Sink Connections. The sink outlet waste connec- tion from each sink compartment shall be 1 1 ⁄ 2 in. (38 mm) in size and each connection shall be fitted with a quick-opening gate valve.

(b) Combined Horizontal Waste Piping. The com- bined horizontal waste piping into which the sink outlets connect shall be 3 in. (76 mm) installed with the center line 11 in. (0.28 m) below the bottom of the sink and properly hung and braced from the sink reinforcement and supports. This waste pipe shall connect to a single 3-in. (76 mm) ball valve that shall serve to regulate the total discharge flow rate. The pipe connected to the ball valve outlet shall turn downward 90 deg and shall terminate 1 in. (25 mm) above the rim and at the center line of the floor sink.

(c) Floor Sink to Interceptor Piping. A trap fitting shall be connected to the outlet of the floor sink, of a size appropriate for the flow rate tested, but not less than 3 in. (76 mm). Horizontal piping of the same size and 3 ft (0.91 m) in length with a vent shall be connected between the floor sink elbow and the vertical waste riser, which shall extend downward to connect to the grease interceptor inlet by means of an elbow and a short horizontal nipple.

(d) Interceptor Discharge. The discharge pipe from the grease interceptor outlet to the skimming tank shall be the same size as the inlet pipe. It shall have a minimum pitch of 1 ⁄ 8 in. per ft (10 mm per m) and shall be provided with a 2-in. (50 mm) vent properly located to prevent siphoning of the interceptor.

(e) Interceptor Connections. If the inlet and/or outlet connections of the interceptor are larger than the inlet pipe necessary to provide the required flow rate, reduc- ing couplings shall be permitted to be used. 3.3 Preliminary Test Procedure 3.3.1 Media Analysis. before conducting rating tests on any grease interceptor, simple analysis of the test media shall be made to determine that it complies with the following characteristics: (a) Water: hydrogen ion concentration (pH value from 6.0 to 8.0)

ASME A112.14.3:2001 pdf download