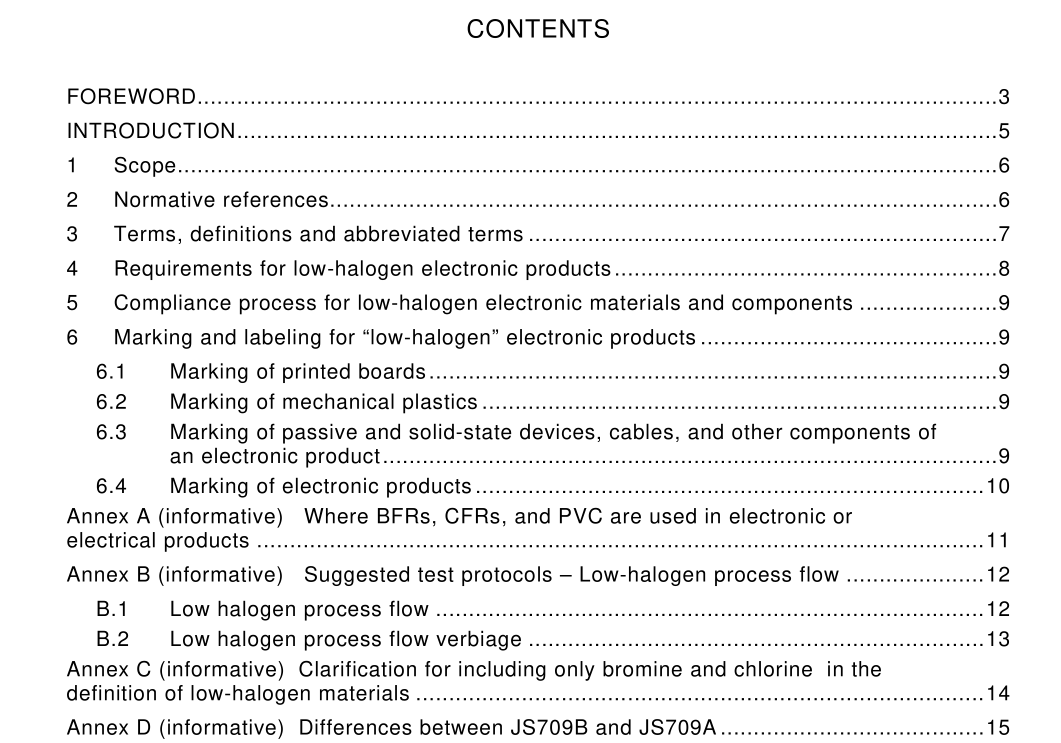

IEC PAS 63015:2016 pdf download.Definition of “Low-Halogen” for electronic products

1 Scope

This document provides terms and definitions for “low-halogen” electronic products that have the potential to contain the halogens bromine (Br) and chlorine (Cl) from the use of BFRs, CFRs, and PVC, and recommends methods for marking and labeling. This standard may be applied to all nonmetallic and nonceramic materials within electronic products including, but not limited to, materials in the following components commonly found in electronic products: 1 ) transistors, integrated circuits, modules consisting mainly of integrated circuits (e.g. multichip, hybrid), and memory modules; 2) resistors, capacitors, relays, inductors, and connectors; 3) printed circuit board assemblies (PCBAs) including components; 4) plastic in cables, sockets, switches and external wiring; 5) mechanical plastics (enclosures, fans, etc.); 6) films, tapes, inks, and adhesives; 7) soldering flux residues (when present); 8) sound, shock, and vibration dampeners (foams, resins, etc.). This document establishes the maximum concentration level for the halogens bromine (Br) and chlorine (Cl) from the use of BFRs, CFRs, and PVC. While the halogen group contains fluorine, chlorine, bromine, iodine, and astatine, this document will use the term “low-halogen” to refer only to bromine and chlorine. Refer to Annex C for further explanation for exclusion of astatine, iodine and fluorine. NOTE The definition of “low-halogen” is different from the term “halogen-free” as described in IEC 61 249-2 sectional standard related to non-halogenated base material and as defined in the J-STD-609A marking and labeling standard; standards that pertain only to printed boards and are currently in use in the electronics and solid-state industries. BFRs, CFRs, and PVC in materials that may be used during processing, in product delivery systems, or in packaging, but do not remain within the final product are not included in the scope of this document.

3 Terms, definitions and abbreviated terms

For the purposes of this document, the terms, definitions and abbreviated terms given in JESD88 and/or IPC-T-50 and the following apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: • IEC Electropedia: available at http://www.electropedia.org/ • ISO Online browsing platform: available at http://www.iso.org/obp 3.2 brominated/chlorinated flame retardants BFR/CFR flame retardants that contain bromine and/or chlorine Note 1 to entry: These compounds are typically added to or reacted into polymers such as certain epoxy resins and thermoplastics to reduce their flammability. Examples include, but are not limited to, tetrabromobisphenol-A (TBBPA), brominated epoxy resins, and polybrominated diphenyl ethers (PBDEs). 3.3 congener member of the same kind, class or group of compounds with similar structures and similar chemical properties 3.4 copolymer polymer derived from more than one species of monomer [SOURCE: IUPAC] 3.5 electronic device device whose operation depends on the conduction of electrons and/or holes in vacuum, gas, or semiconductor Note 1 to entry: Examples of electronic devices include transistors, integrated circuits, hybrid integrated circuits, and modules containing active electronic components. 3.6 electronic product item containing one or more electronic devices performing major functions 3.7 low-halogen meeting the criteria established in Clause 4 of this document Note 1 to entry: Low halogen electronic products may still contain some halogens, providing, of course, that each material in them meets the requirements in Clause 4. 3.8 plastic any of a group of synthetic or natural organic compounds produced by polymerization, optionally combined with additives (organic or inorganic fillers, modifiers, etc.) into a homogeneous material capable of being molded, extruded, or cast into various shapes and films 3.9 polymer alloy polymer blend (considered to be an alloy) that contains either a crystallizable component or two relatively rigid or amorphous polymers

5 Compliance process for low-halogen electronic materials and components

An electronic product often contains many materials/components from a complex and global supply chain. Therefore, all individual entities or suppliers within the chain have to be required to take responsibility for ensuring that the materials/components that they supply meet the requirements of this document. Each supplier/individual entity within the supply chain is only responsible to prove compliance to their respective customer for the material/component that they supply. Any material/component that is declared to be “low-halogen” as per Clause 4 herein shall be supported by proof that substantiates the claim. Since there is not a single, simple, cost-effective, and reliable test method that covers the spectrum of materials/components included in electronic products, customers and suppliers should mutually agree on the best method to demonstrate compliance to this document. If analytical testing is used, elemental Br and Cl analysis is the most expedient and cost effective to perform (IEC 62321 provides screening and analytical test methods for some but not all of the substances within the scope of this document). If results detect Br or Cl above 1 000 ppm threshold, the supplier should determine if the source of the Br or Cl is from flame retardants, PVC, PVC congeners, PVC block polymers, PVC copolymers, or polymer alloys containing PVC. The proof of compliance documents may include material declarations, datasheets and/or analytical data.

IEC PAS 63015:2016 pdf download